MISCELLANEOUS

Miscellaneous

FUTURE PRECISION’s machining is applicable to a wide range of materials and process selections. Its professional precision machining capabilities enable the production of high-performance components across a wide range of industries. These include not only aerospace, medical devices, electronics, and automotive manufacturing, but also sectors such as energy, defense & military, semiconductors & optics, industrial machinery & automation, consumer electronics, tooling & mold making, marine & transportation, and scientific & research instruments. The material selection depends on specific application requirements, including strength, wear resistance, and thermal stability.

Types of Miscellaneous Components We've Made

At FUTURE PRECISION, there are multiple metal material options available – Common materials include stainless steel, aluminum alloy, titanium alloy, mold steel, nano tantalum powder, nano tungsten powder, spherical tantalum powder, spherical tungsten powder, cobalt-chromium alloy, nickel-chromium alloy, copper, and more.

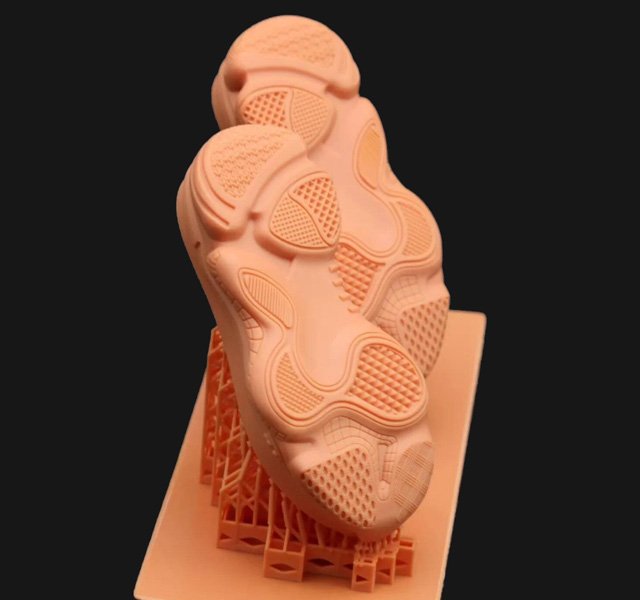

The biggest advantage of this technology is that it can reduce development costs and optimize product design – For example, replacing solid structures with complex yet rational designs results in lighter-weight parts with superior mechanical properties. Metal 3D printing significantly shortens the development cycle, reducing overall manufacturing and development costs by approximately 50%.

Utilizing SLM (Selective Laser Melting) technology, the printed components exhibit excellent stability, high strength, precision, and ultra-long lifespan.

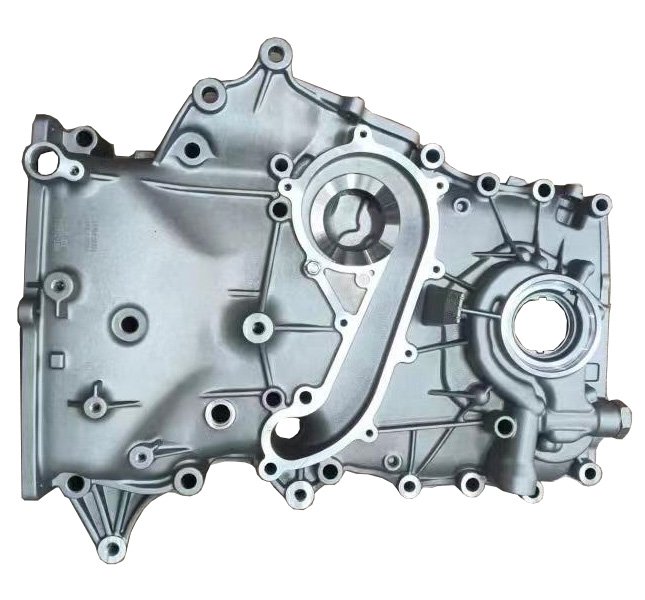

The choice of materials for sports shoe soles directly affects key performance factors such as cushioning, wear resistance, and weight. Modern athletic shoes typically employ a multi-layer composite structure, with different materials used for specific functional zones. The most common materials include:

EVA (Ethylene-Vinyl Acetate) – Lightweight and cost-effective, widely used in midsole cushioning.

TPU (Thermoplastic Polyurethane) – Durable and flexible, often used for stability plates and outsoles.

PU (Polyurethane) – Offers superior rebound and longevity, commonly found in performance midsoles.

PEBA (Polyether Block Amide) – High energy return, used in premium running shoes for elite responsiveness.

Rubber (Natural/Synthetic) – Provides excellent traction and durability, primarily used for outsole treads.

This combination of materials ensures optimal balance between shock absorption, stability, and wear resistance in athletic footwear.

For FUTURE PRECISION, anything can be 3D printed. Even the most complex structures can be formed in a single step, eliminating the need for welding and saving significant time.

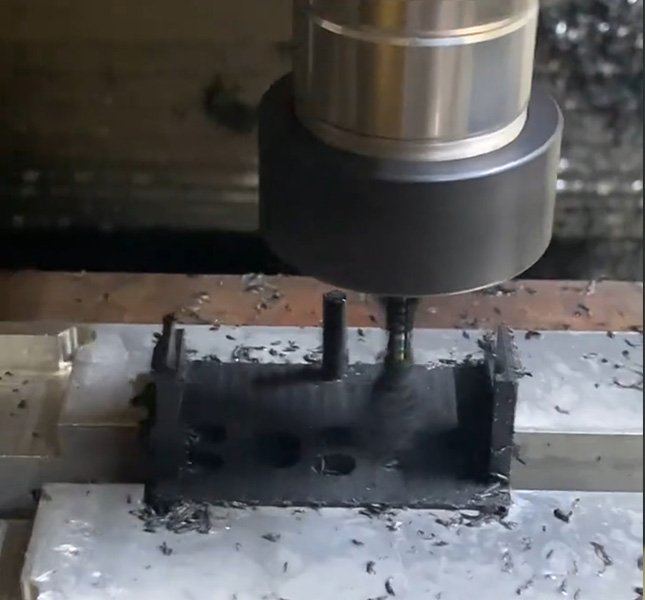

This is a batch of gears processed by FUTURE PRECISION for our customer. The product is used in smart home systems, automotive applications, and other fields, with the final products exported to a European country.

We have found that POM (polyoxymethylene) is highly suitable for precision machining due to its excellent dimensional stability, low friction, and ease of processing. It is commonly used in high-precision mechanical components. By selecting appropriate tools and parameters, an accuracy of ±0.02mm or even higher can be achieved. The material is uniform, resists tool sticking during turning, milling, and drilling, and can achieve a high surface finish. Additionally, its low water absorption rate (<0.2%) minimizes post-machining dimensional changes due to humidity, reducing the risk of deformation.

However, POM has some drawbacks—it is not heat-resistant, and prolonged exposure to temperatures above 80°C may affect its precision. In such cases, copolymer POM (with slightly better heat resistance) should be selected. It is also important to note that POM decomposes at high temperatures, releasing toxic fumes, so machining personnel must take proper safety precautions. Furthermore, POM is sensitive to UV light, requiring stabilizers for long-term outdoor use.

MC nylon, as an engineering plastic, is known for "replacing steel with plastic while delivering superior performance." It has an extremely wide range of applications, with a temperature resistance ranging from -100°C to +120°C for long-term use.

It boasts multiple unique properties, including light weight, high strength, self-lubrication, wear resistance, corrosion resistance, and insulation, making it one of the most widely used engineering plastics across nearly all industrial fields. MC nylon is manufactured in various grades based on its intended use, including:MC Nylon (Ivory White), MC901 (Blue),PA6 + Oil (Green) – Self-Lubricating Nylon,PA6 + Molybdenum Disulfide (Gray-Black)and PA6 + Solid Lubricant (Gray)

The batch of nylon wheel manufactured by FUTURE PRECISION is made of MC Nylon (ivory white), Similar in properties to nylon 66, it has excellent overall performance, high strength, stiffness, and hardness, as well as good creep resistance, wear resistance, heat aging resistance, and machinability

FUTURE PRECISION applies surface oil spray treatment to ABS products, coating them with flame-retardant paint. This method enhances the fire resistance of the ABS surface without altering its inherent material properties.

In products such as electrical enclosures, sockets, and switches, materials must possess a certain level of flame retardancy to prevent fires caused by electrical faults. Flame-retardant ABS meets these requirements. For example, computer cases, monitor housings, and similar components are typically made of flame-retardant ABS to improve product safety.

ABS plays a crucial role in balancing lightweight design and functionality in automotive manufacturing. It is widely used for interior parts, dashboards, center console panels, air vents, and other components. Thanks to its smooth surface finish and ease of dyeing, ABS meets both aesthetic and durability demands.

Additionally, ABS is used in various other fields, including consumer goods, construction, and industrial equipment.