AUTOMOTIVE COMPONENTS

Automotive Components

The automotive industry demands parts that are highly precise, durable, and consistent, while also supporting mass production, stringent reliability standards, and cost efficiency. FUTURE PRECSION compies with industry regulations, control costs, and responds quickly to evolving market needs.

Key Processing Technologies

1. CNC Machining

Its ultra-high precision is essential for critical parts like turbine blades and brake calipers. The rapid reprogramming allows small-batch customization and quick transitions between different parts.CNC machining is also capable of machining irregular surfaces, deep holes, and precision threads.Moreover, it Works well with aluminum, stainless steel, titanium, and engineering plastics.

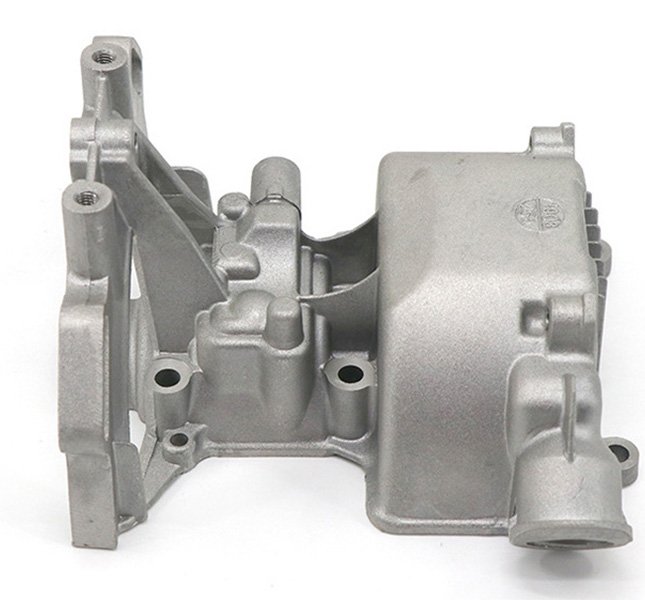

2. Die Casting (High-Pressure Casting)

Its high efficiency allows producing parts in seconds, ideal for mass production of housings and structural components. The near-net shape minimizes post-machining but requires strict burr and flash control.Normally lightweight is also an advantage, because aluminum and magnesium are commonly used in die casting.

Of course, rapid tooling, 3D prototype, and surface finishing are also key processes in automotive coponents machining. By leveraging these advanced technologies, FUTURE PRECISION can meet the automotive industry’s demands for precision, efficiency, and innovation, ensuring high-performance vehicles for the future.

Types of Automotive Equipment Components We've Made

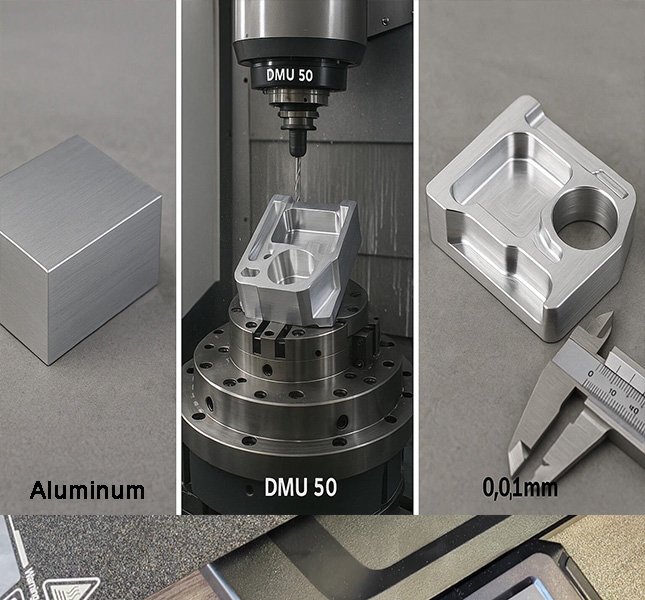

Machining Case Study:

This component is an automotive part made of Aluminum 6061, with exceptionally high precision requirements of ±0.01mm.

Before Machining (Raw Material State)

As shown in the first image, the raw material is a plain aluminum block with no pre-formed features. While it appears ordinary, its internal metallurgical structure, surface flatness, and material properties must meet strict standards before machining can begin.

During Machining (In-Process)

The second image captures the machining phase, performed on a DMG DMU50 5-axis CNC machine. The CNC follows programmed toolpaths to meticulously refine contours, internal cavities, and holes. The precision of the machine and cutting tools is clearly visible during operation.

After Machining (Finished Part)

The final image showcases the completed part! It features a smooth tactile finish with a surface roughness of Ra0.8 and maintains the required ±0.01mm dimensional accuracy. After full inspection, the part passed all quality checks, and the customer expressed great satisfaction.

Precision cylindrical gears machined by FUTURE PRECISION play a vital role in modern industry. Did you know? These meticulously engineered gears silently power our daily lives, serving as indispensable core components—especially in the new energy vehicle and aerospace sectors.

The advancement of new energy vehicles relies heavily on precision cylindrical gears. They ensure stable power transmission, enabling smooth and efficient vehicle operation. Meanwhile, in the aerospace industry, these gears are mission-critical. Every phase of flight—from takeoff to cruising to landing—depends on their flawless performance.

These are some of the metal parts for automobiles & motorcycles we’ve manufactured at FUTURE PRECISION. We have extensive experience in producing components for both traditional fuel vehicles and new energy vehicles (NEVs). Even for a single part like a valve spool, we’ve machined hundreds of variations in size and design. Automotive metal components are our longest-standing specialty—some of our earliest clients from the company’s founding days still work closely with us today.

What We Uphold (Since Day One):

✔ Superior Quality – Precision-engineered for reliability

✔ Competitive Pricing – Cost-effective without compromise

✔ On-Time Delivery – Keeping your production on track

✔ Responsive Service – Solutions tailored to your needs

FUTURE PRECISION CNC machining services deliver high-quality parts for critical components such as engines, transmissions, and suspension systems. Whether you need custom prototypes or large-scale production, we ensure the highest precision and durability for every part.