AEROSPACE EQUIPMENT COMPONENTS

Home » Aerospace Equipment Components

Aerospace Equipment Components

Aerospace component machining represents one of the most precision-demanding and reliability-critical sectors in manufacturing, requiring high performance under extreme conditions (high temperature, high pressure, and intense vibration). Its core characteristics and requirements include: extreme environment adaptability, ultra-Lightweighting with high strength, micron- or even nano-level precision,near-zero effect tolerance.FUTURE PRECISION possesses key aerospace manufacturing technologies, such as precision CNC machining and additive manufacturing (3D printing).

Precision CNC Machining

5-Axis/7-Axis Multi-Axis Machining: For complex contours (e.g., impellers, engine casings).

Ultra-Precision Cutting: Diamond tool machining for optical-grade surfaces (e.g., infrared sensor components).

3D Printing

Metal 3D Printing (SLM/DED): Direct fabrication of intricate internal flow channels (e.g., rocket engine fuel nozzles).

Composite Material Printing: Integrated lightweight structural forming (e.g., UAV wings).

Precision CNC Machining

5-Axis/7-Axis Multi-Axis Machining: For complex contours (e.g., impellers, engine casings).

Ultra-Precision Cutting: Diamond tool machining for optical-grade surfaces (e.g., infrared sensor components).

3D Printing

Metal 3D Printing (SLM/DED): Direct fabrication of intricate internal flow channels (e.g., rocket engine fuel nozzles).

Composite Material Printing: Integrated lightweight structural forming (e.g., UAV wings).

Types of Aerospace Equipment Components We've Made

3D-Printed Aluminum Alloy Lightweight Components for Drones

Leveraging advanced additive manufacturing technology, FUTURE PRECISION produces high-performance drone components using premium aluminum alloys.

✓30% Lighter – Yet stronger than conventional parts. And weight reduction enhanced flight efficiency and payload capacity

✓Unibody Design – Enhances heat dissipation & structural reliability.

No Molds Needed – Complex geometries printed in one go.

✓Versatile Applications – Aerial photography, logistics, defense, agriculture & more.

This is the future of drone engineering!

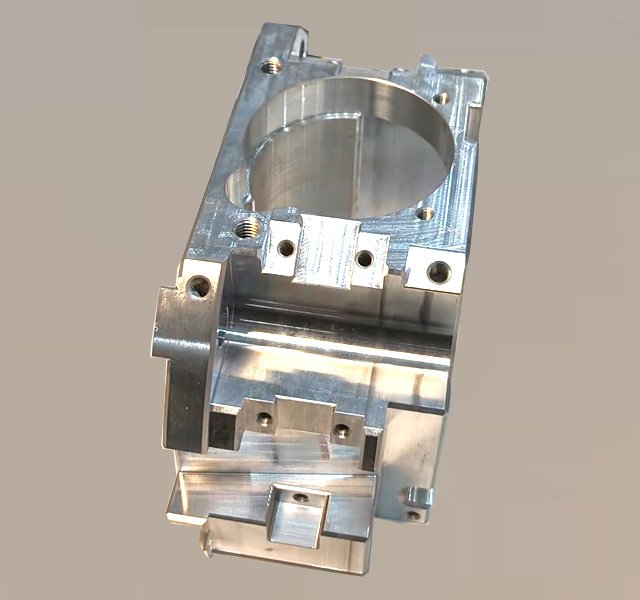

This part may look simple, but it's actually quite tricky to handle. Finally, it's our turn to give it a try.