3D PRINT PROTOTYPE

REQUEST A 3D PRINTING QUOTE

Please provide 3D drawings in formats that are compatible with 3D printing, such as STL, OBJ, 3MF, or AMF files.

🔐All uploads are kept secure and confidential.

Quality 3D Printing Service

✓Unmatched precision: Achieve tolerances as tight as ±0.02mm for critical dimensions.

✓Cutting-edge technology: leverage our state-of-the-art in-house equipment for highly complex geometries.

Best You Need, Best We Provide!

WHAT WE GOOD AT 3D PRINT PROTOTYPE PROCESSES

Selective Laser Sintering(SLS)

It uses a high-precision laser to selectively irradiate and melt special additive material powder. This melted material acts as a binder, fusing the metal powder particles together to form the desired 3D structure. Once the layering process is complete, the final metal 3D-printed part is achieved.

Fused Deposition Modeling (FDM)

FDM builds durable, functional parts by extruding thermoplastic filaments layer by layer. Known for its cost-effectiveness and versatility, it supports engineering-grade materials like ABS, PLA, and PETG—making it ideal for rapid prototyping, functional testing, and low-volume production of automotive components, consumer goods, and industrial parts.

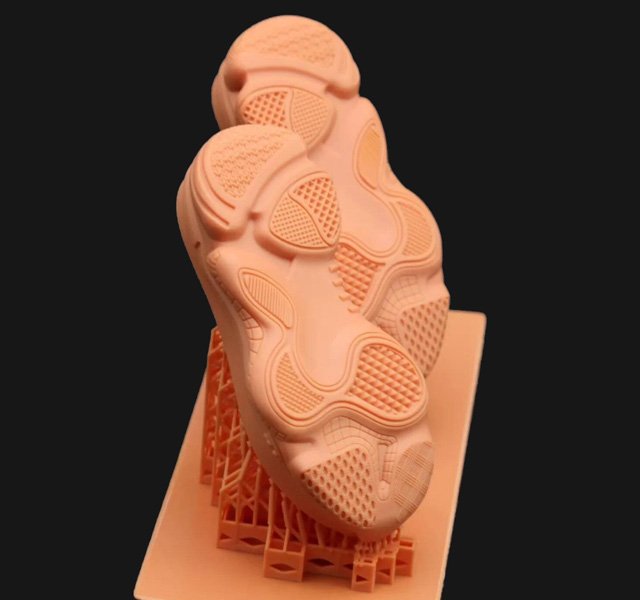

Stereolithography (SLA)

SLA uses a precision laser to photopolymerize liquid resin, creating parts with ultra-smooth surfaces and intricate details. Renowned for its high accuracy and fine resolution, SLA is the preferred choice for detailed prototypes, medical and dental models, jewelry casting, and any application requiring flawless finish and dimensional precision.

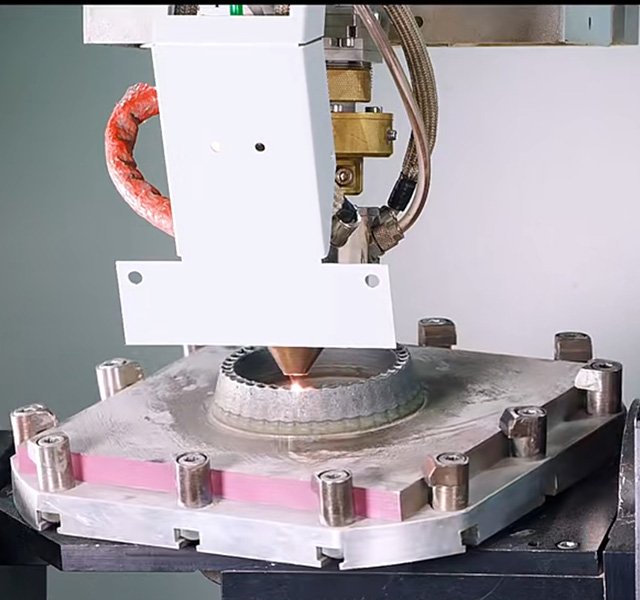

Selective Laser Melting(SLM)

SLM utilizes a high-energy, fine-focus laser to fully melt metal powder, producing parts with exceptional dimensional accuracy, high density, and superior mechanical properties. Ideal for rapid manufacturing, SLM excels in creating high-performance metal components for demanding applications in aerospace, medical, and automotive industries.

Direct Metal Laser Sintering (DMLS)

DMLS fuses fine metal powders—such as titanium, stainless steel, and aluminum—using a high-power laser, resulting in strong, lightweight parts with complex geometries. Renowned for its high strength-to-weight ratio, DMLS is widely used in aerospace components, medical implants, and high-performance automotive parts.

Multi Jet Fusion (MJF)

MJF enables high-speed production of precision parts with uniform strength and durability. By fusing nylon powder layer by layer, it delivers consistent mechanical properties and fine detail resolution, making it perfect for functional prototypes, end-use parts, and low-volume manufacturing across industries.

From Design To Prototyping To Production

With 7+ years of industry experience, ISO 9001:2015 certification, and advanced metrology inspections (CMM), we deliver unmatched precision and reliability in every part. Our comprehensive surface finishing services—including polishing, painting, and powder coating—ensure both superior aesthetics and enhanced functional performance for your components.

Why choose us?

vProven expertise – 15+ years in high-precision manufacturing

✓Certified quality – ISO 9001:2015 compliant processess

✓Rigorous inspections – CMM-verified accuracy for flawless results

✓Premium finishes – Custom polishing, painting & coating solutions

CUSTOMIZE YOUR 3D PRINTING SERVICE SOLUTION

Rapid Prototyping

We provide high-quality rapid prototyping services in China, offering more competitive 3D printing prices and faster delivery times. Utilizing the latest rapid prototyping technologies, we help you overcome design challenges by collaborating closely to refine your 3D-printed prototypes. Our services include functional testing and engineering verification to ensure your product meets the highest standards.

Rapid Manufacturing

FUTURE PRECISION is your premier 3D printing manufacturing partner in China. We provide a comprehensive range of services, from efficient rapid prototyping to full-scale production of 3D-printed parts. With our extensive machining experience and strong resource integration capabilities, we can handle projects of any scale, ensuring your parts consistently meet the highest quality standards.

Custom 3D Printing

We provide one-stop rapid 3D printing services and cost-effective custom 3D printing solutions. Whether you need production-grade materials, complex geometries, tight tolerances, or intricate details, FUTURE PRECISION can deliver. Partnering with our 3D printing factory, you’ll receive parts built precisely to your specifications throughout the entire prototyping and manufacturing process.

OUR HAPPY CUSTOMERS

THOUSANDS OF CUSTOMERS TRUST US TO DELIVER

We help you choose the right prototype manufacturer with personalized, one-on-one technical support and rapid responses—usually within just a few hours. Our prices are highly competitive, often up to 30% lower than those in Europe and the US, giving you outstanding value without compromising quality.

MATERIALS OF 3D PRINT PROTOTYPE

Material | Process | Key Properties | Max Part Size (in) | Min Feature Size (in) | Mechanical Properties |

Aluminum (AlSi10Mg) | DMLS 3D Printing | Lightweight, high strength-to-weight ratio, heat & corrosion resistant, fatigue-resistant | 31.5 X15.7X 19.7 | 0.015 | Tensile: 50 ksi Elongation: 8% Hardness: 59 HRB |

Cobalt Chrome (Co28Cr6Mo) | DMLS 3D Printing | High-strength superalloy, excellent creep & corrosion resistance, thermal stability | 9.6X9.6X13.0 | 0.006 | Tensile: 176 ksi Elongation: 14% Hardness: 38 HRC |

Inconel 718 | DMLS 3D Printing | Nickel-chromium superalloy, extreme heat/corrosion resistance, aerospace-grade | 31.5X15.7X19.7 | 0.006 | Tensile: 208 ksi Elongation: 18% Hardness: 46 HRC |

Stainless Steel 17-4PH | DMLS 3D Printing | Precipitation-hardened, high hardness, corrosion & wear resistant | 9.6X9.6X13.0 | 0.006 | Tensile: 198 ksi Elongation: 13% Hardness: 42 HRC |

Stainless Steel 316L | DMLS 3D Printing | Acid-resistant, high ductility, general-purpose corrosion resistance | 9.6X 9.6X13.0 | 0.006 | Tensile: 92 ksi Elongation: 58% Hardness: 94 HRB |

Titanium (Ti6Al4V) | DMLS 3D Printing | Biocompatible, aerospace-grade strength, lightweight, excellent corrosion resistance | 31.5X15.7X19.7 | 0.006 | Tensile: 144 ksi Elongation: 18% Hardness: 33 HRC |

Material | Process | Key Properties | Max Part Size (in) | Min Feature (in) | Mechanical Properties | Special Notes |

ABS-Like Black (Accura 7820) | SLA | Glossy/matte finish, moisture-resistant, molded appearance | 10X10X10 | 0.01 | Tensile: 7 ksi E-mod: 435 ksi HDT: 124°F Elong: 5% | Best for cosmetic prototypes |

ABS-Like Gray (Accura Xtreme) | SLA | Injection-molded feel, heat-tolerant, flexible | 29X25X21 | 0.01 | Tensile: 5.8 ksi E-mod: 290 ksi HDT: 144°F Elong: 9% | Large-format parts |

ABS-Like MicroFine? | SLA | Micro-resolution (0.0025 in), opaque green/gray | 5X5X2.5 | 0.0025 | Tensile: 8.7 ksi E-mod: 377 ksi HDT: 138°F Elong: 8% | High-detail applications |

ABS-Like Clear (WaterShed) | SLA | Near-colorless transparency, low moisture absorption | 29X25X21 | 0.01 | Tensile: 7.9 ksi E-mod: 421 ksi HDT: 123°F Elong: 6% | Requires post-finishing |

Carbon EPX 86FR | Carbon DLS | Flame-retardant (UL 94 V-0), chemical-resistant, high toughness | 7.4X4.6X12.8 | 0.02 | Tensile: 13 ksi E-mod: 480 ksi HDT: 275°F Elong: 10% | Aerospace/compliance |

Carbon FPU 50 | Carbon DLS | PP-like flexibility, highest elongation (200%) | 7.4X4.6X12.8 | 0.02 | Tensile: 4 ksi E-mod: 100 ksi Elong: 200% | Hinges, seals |

Ceramic-Filled (BASF 3280) | HPS | Extreme stiffness (10 GPa), short-run tooling, >536°F HDT | 9.8X5.5X19.4 | 0.01 | Tensile: 12.6 ksi E-mod: 1,537 ksi HDT: 543°F Elong: 1.3% | Molds, high-temp fixtures |

PA12 Black (MJF) | MJF | Economical, wear-resistant, living hinges | 11.1X14.9X14.9 | 0.02 | Tensile: 7.1 ksi E-mod: 276 ksi HDT: 347°F Elong: 21% | Functional end-use parts |

PA12 Glass-Filled (SLS) | SLS | 40% glass-filled, high stiffness, thermal resistance | 10.6X12.6X16 | 0.03 | Tensile: 7.2 ksi E-mod: 508 ksi HDT: 315°F Elong: 5% | Low wear applications |

PC-Like Clear (Accura 60) | SLA | High stiffness, translucent, fine details | 29X25X21 | 0.01 | Tensile: 10.8 ksi E-mod: 508 ksi HDT: 129°F Elong: 7% | Optical prototypes |

Polypropylene Natural | SLS | True PP, chemical-resistant, lightweight | 12.6X10.6X10.6 | 0.04 | Tensile: 2.6 ksi E-mod: 123 ksi Elong: 15% | Fluid containers |

Finish Type | Description | Best For | Materials/Processes | Surface Quality (RA μin) | Additional Notes |

As-Printed | Supports removed; retains natural print texture. May have visible support nibs. | Functional parts, low-cost/fast-turn projects | All processes | 250+ | Minimal handling; fastest lead time |

Standard Finish | Support nibs sanded, bead-blasted for uniform matte finish. Layer lines may remain. | General prototyping, non-cosmetic parts | SLA, SLS, MJF, DMLS | 100–150 | Balances cost and aesthetics |

Custom Finishing | Aesthetic enhancements (painting, textures, decals, soft-touch coatings). | High-visibility/cosmetic parts | All materials | Varies | Includes color matching, masking |

Smoothing | Reduces roughness significantly (64–100 μin RA). | MJF parts requiring smooth surfaces | PA12 Black, Glass-Filled PA12, TPU | 64–100 | Improves tactile feel |

Primer Application | Prepares surfaces for painting or improves cosmetics. | MJF parts needing coatings | MJF plastics | – | Base layer for further finishes |

Taps & Inserts | Adds threaded features for assembly. | Functional mechanical parts | MJF, SLS, SLA | – | Enhances part utility |

Clear Coat | Enhances translucence/gloss on clear materials. | Optical/display parts | PolyJet Clear, SLA resins | – | Improves clarity & scratch resistance |

Post-Machining | Secondary CNC machining for precision tolerances/surface quality. | High-tolerance metal parts | DMLS metals | <32 (machined) | Critical for mating surfaces |

Heat Treatments | Stress relief, aging (e.g., H900 for 17-4PH). | Metal parts requiring strength | DMLS (Stainless, Inconel) | – | Enhances mechanical properties |

Brushed Finishes | Aesthetic brushed textures (various grits). | Decorative metal parts | DMLS metals | 50–125 | Customizable finish levels |

Metal Plating | Adds conductive/decorative metal layers. | EMI shielding or cosmetic upgrades | Plastics/metals | – | Nickel, chrome, or gold options |

Dyeing | Permanently colors plastic parts. | Branded/aesthetic parts | MJF/SLS nylons | – | No impact on strength |

3D PRINTING HELP & FAQs

What is your typical lead time for 3D printing orders?

We offer fast turnaround options:

✓Standard: 3–5 business days for most prototypes;

✓Rush: As fast as 24–72 hours (depending on complexity and technology);

✓Production runs: 1–2 weeks (with volume discounts available).

What tolerances can your 3D printers achieve?

Our systems deliver industry-leading precision:

✓SLA/DLP: ±0.02–0.05 mm

✓SLS/MJF: ±0.1–0.3 mm

✓DMLS (Metal): ±0.05–0.1 mm

For critical features, submit a 2D drawing—we’ll validate tolerances before production.

What if I’m not satisfied with the parts?

✓Pre-Production Review: We’ll confirm specs and tolerances upfront.

✓In-Process QC: CMM inspection and material certifications available.

✓Post-Delivery Support: If issues arise, we’ll remake or refund per your requirements.

How much does a 3D printed part cost?

✓Material (e.g., standard nylon vs. aerospace titanium)

✓Volume (discounts for 50+ units)

✓Post-Processing (e.g., polishing, annealing)

✓Request a quote online—we respond within 4 business hours with competitive pricing.

3D PRINTING PARTS

START YOUR 3D PRINTING PROJECT TODAY

Transform your ideas into reality with our complete 3D printing services – combining manufacturing excellence, rapid delivery, and budget-friendly solutions for every stage from prototype to end-use parts. Upload your CAD file for an instant quote or consult our engineers for design optimization.